In the realm of advanced materials and biomechanical engineering, a groundbreaking innovation has emerged that could redefine the future of robotics, prosthetics, and even human augmentation. Researchers have developed artificial muscles made from carbon nanotubes that outperform natural muscles by a staggering factor of ten. This leap in actuator technology promises to revolutionize industries where strength, flexibility, and efficiency are paramount.

The concept of artificial muscles isn’t new, but the limitations of existing materials have long hindered progress. Traditional actuators, such as pneumatic or hydraulic systems, are often bulky, slow, or energy-inefficient. Natural muscles, while elegant in their design, have inherent biological constraints. Carbon nanotube muscles, however, combine the best of both worlds—delivering unprecedented performance while maintaining a lightweight and compact form.

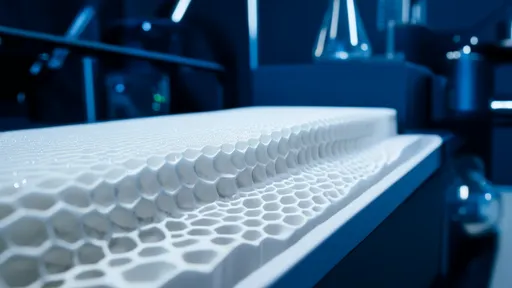

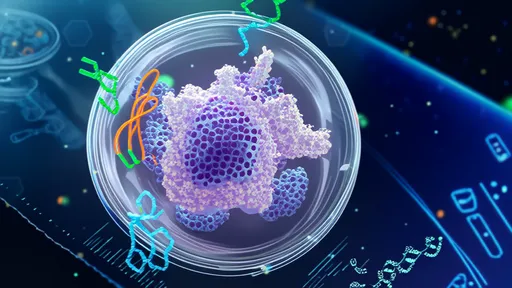

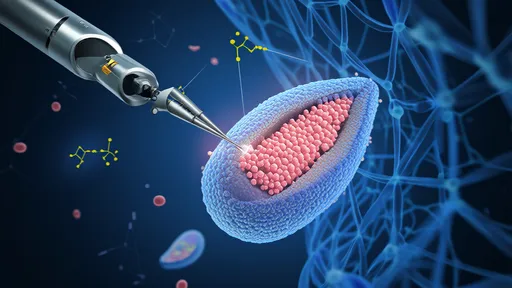

What makes carbon nanotube muscles so extraordinary? At the heart of this technology lies the unique properties of carbon nanotubes (CNTs). These cylindrical nanostructures, composed of rolled-up graphene sheets, exhibit exceptional mechanical strength, electrical conductivity, and thermal stability. When engineered into yarn-like structures, CNTs can contract and expand with remarkable speed and force in response to electrical stimuli, mimicking the behavior of natural muscle fibers.

One of the most striking advantages of CNT muscles is their strength-to-weight ratio. Unlike biological muscles, which fatigue over time, these synthetic counterparts maintain their performance under repeated use. Tests have shown that they can generate forces up to ten times greater than human skeletal muscles of the same size. This makes them ideal for applications requiring sustained power output, such as exoskeletons for industrial workers or high-performance robotic limbs.

Beyond raw strength, carbon nanotube muscles offer unparalleled versatility. They can operate across a wide temperature range, from cryogenic conditions to high-heat environments where traditional actuators would fail. This resilience opens doors for use in aerospace, deep-sea exploration, and even space missions. Additionally, their ability to respond to electrical signals with precision allows for fine-tuned control, enabling delicate tasks like surgical robotics or adaptive textiles that adjust to environmental changes.

The development of CNT muscles hasn’t been without challenges. Early iterations struggled with scalability and consistency in performance. However, recent breakthroughs in nanofabrication techniques have addressed many of these issues. By optimizing the alignment and density of nanotubes within the yarn, researchers have achieved more predictable and reproducible actuation. Advances in coating technologies have also improved durability, ensuring these muscles can withstand millions of cycles without degradation.

Real-world applications are already on the horizon. In the medical field, CNT muscles could lead to next-generation prosthetics that closely mimic natural movement, offering amputees a level of dexterity previously unimaginable. For robotics, these actuators could enable the creation of machines capable of feats like lifting heavy loads with human-like grace or navigating complex terrains with agility. Even the fashion industry is exploring their potential, with prototypes of "smart" clothing that adjusts fit or ventilation based on the wearer’s activity.

Despite the excitement, questions remain about large-scale production and integration. The cost of high-quality carbon nanotubes, though decreasing, is still a barrier for widespread adoption. Researchers are also investigating how to seamlessly incorporate these muscles into existing systems, ensuring compatibility with power sources and control mechanisms. Nevertheless, the pace of progress suggests these hurdles will be overcome in the coming years.

As we stand on the cusp of this technological revolution, the implications are profound. Carbon nanotube muscles represent more than just an improvement over existing actuators—they offer a glimpse into a future where the boundaries between biology and machinery blur. Whether enhancing human capabilities or creating robots with unprecedented agility, this innovation is poised to transform how we interact with the physical world.

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025